Contact ACE

Contact ACE

Latest News

The Benefits of Using Robotics for Tank Inspections in Refineries

26 July 2023

The inspection of storage tanks in refineries is a vital task that ensures the safety of workers and the public. These tanks often remain inactive for long periods of time, making it essential to perform a thorough inspection before returning them to operation. With the advancement of robotic technology, it has become increasingly common to use robots for inspections, and in this blog, we will discuss why using robotics is a great option for initial inspections.

The Benefits

1. Increased Efficiency

Robotics can perform inspections much quicker than human inspectors, reducing downtime for tanks and minimising any potential disruption to refinery operations. The also eliminate a lot of the preparation work as no scaffolding or alternative access is required.

2. Improved Safety

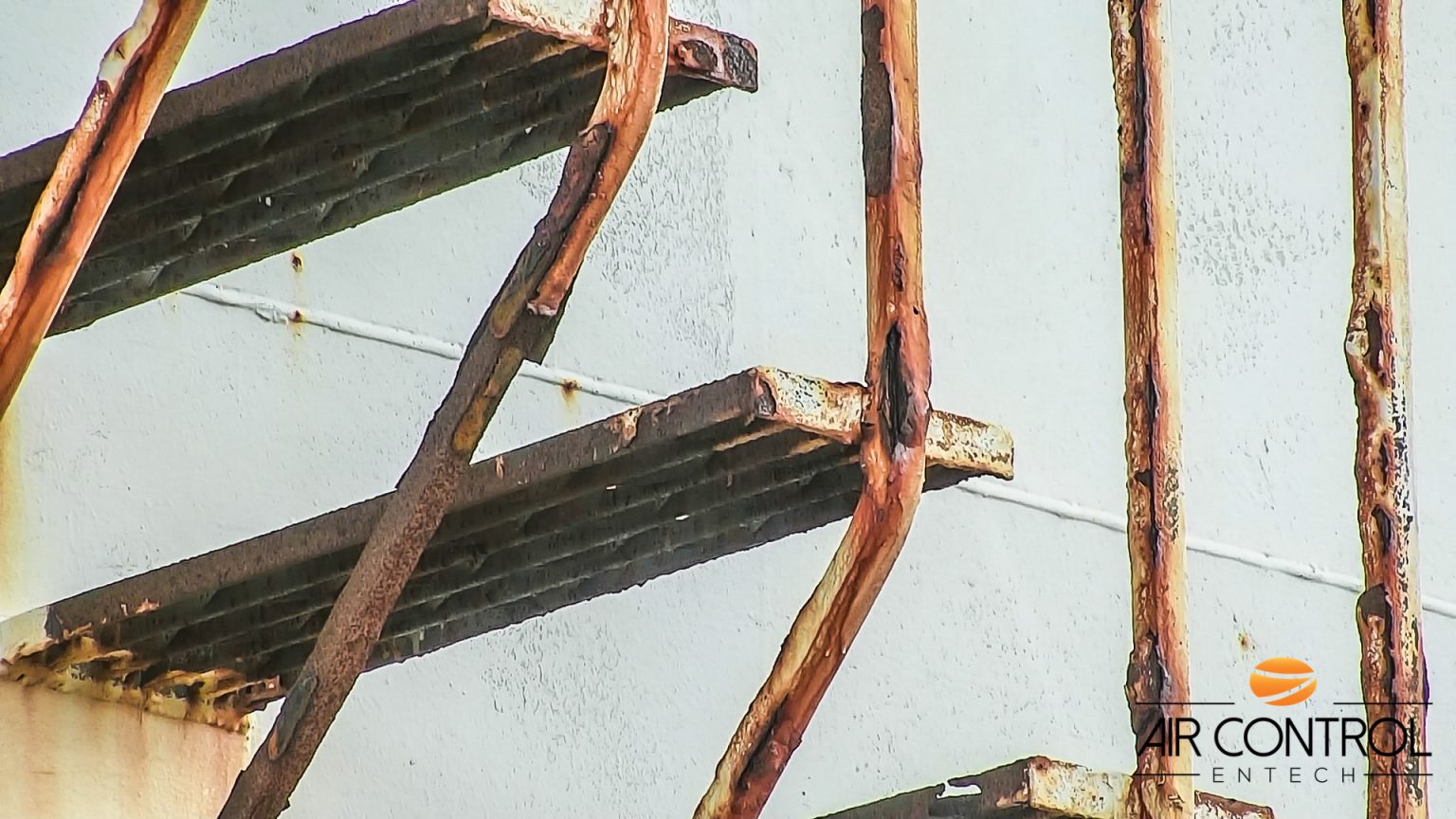

Inspecting tanks manually can be a dangerous job that exposes workers to hazardous conditions such as toxic fumes, confined space entry and potential falls when working at height. Using robotics eliminates the need for human entry into the tanks, reducing the risk of accidents and injuries. Furthermore, robots are equipped with high-resolution cameras and other sensors that allow them to capture images and data in situations that would be difficult or even impossible for human inspectors.

3. Cost-Effective

Robotic inspections can eliminate the need for scaffolding, ropes, and other equipment required for manual inspections, saving time and money. Due to the reduction in access requirements there are less people required for the operation, which is typically completed much faster and thus saving money when factoring day rates of personnel.

4. Data Processing and Analysis

Robotics can rapidly record vast amounts of data, which the inspection team can use to make effective decisions. The data collected by robotics can be processed faster and more efficiently than data collected by human inspectors while offsite at a desk, allowing for quicker diagnoses and corrective actions to be taken. Furthermore, robotics allow for longer inspection periods than human inspectors, making sure that nothing is missed.

5. Verification

Due to the sheer volume of data collected by robotic technologies there is greater confidence that nothing is missed. When a new anomaly is found there’s more chance the area of concern was captured giving greater validity of condition.

Conclusion:

The use of robotics in the initial inspection of storage tanks in refineries can improve efficiency, accuracy, and safety while minimizing disruption and costs. It is an effective method that is increasingly becoming popular in the industry, so it’s worth considering its implementation. Robotics offer many benefits that make it worth the initial investment, improving both the accuracy of inspection and the safety of workers.